ROTA-TAB MSP SERIES ROTARY TABLET PRESS

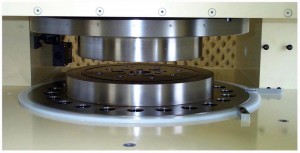

The ROTA-TAB MSP Series is a manually controlled, single-sided, pre-compression press using IPT B, BB, and D-type tooling. Centrally located handwheel adjustments and control panels allows ease of operation. An AC inverter drive provides push-button speed adjustments, with a programmable locked-out jog speed and tablets-per-minute speed.

The ROTA-TAB MSP Series is a manually controlled, single-sided, pre-compression press using IPT B, BB, and D-type tooling. Centrally located handwheel adjustments and control panels allows ease of operation. An AC inverter drive provides push-button speed adjustments, with a programmable locked-out jog speed and tablets-per-minute speed.

This press is available in an upgrade with stainless steal panels, anodizing, plating, and coating. Also available is automatic weight control and force-monitoring tablet control systems.

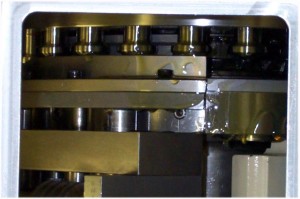

The upper and lower punch compression compartments on the ROTA-TAB MSP Series are totally sealed, preventing any powder or other contaminates from entering. This also allows all moving parts to be lubricated by a continuous lubricating system.

The upper and lower punch compression compartments on the ROTA-TAB MSP Series are totally sealed, preventing any powder or other contaminates from entering. This also allows all moving parts to be lubricated by a continuous lubricating system.

The oil punch seals allows punches to receive a fresh dose of oil after each stroke, eliminating sticking. Imagine the extra life you’ll receive from your cams, turret punch bores and all other associated parts, plus you’ll reduce the time you spend cleaning as compared with other presses.

The oil punch seals allows punches to receive a fresh dose of oil after each stroke, eliminating sticking. Imagine the extra life you’ll receive from your cams, turret punch bores and all other associated parts, plus you’ll reduce the time you spend cleaning as compared with other presses. During tooling changes on the ROTA-TAB MSP Series (since the punch barrels and head are saturated with oil), you can choose to use upper and lower punches designed with replaceable tips.

During tooling changes on the ROTA-TAB MSP Series (since the punch barrels and head are saturated with oil), you can choose to use upper and lower punches designed with replaceable tips.

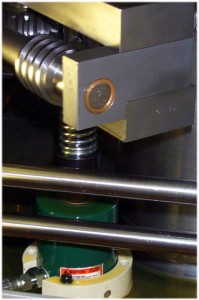

The design of the punch and the press-with a remote hydraulic die removal and installation system – allows you to change out the punch tips and dies without removing the upper and lower punches from the turret. This feature eliminates any oil mess and the use of a hammer to drive dies in and out.

The die table is also interchangeable. You can order a new one and install it at your plant without the cost and downtime of sending your turret out to have the die table custom fitted.

Comprehensive machine enclosures and tamper-proof safety interlock switches are installed on all quick-acess guard doors, assuring the ROTA-TAB MSP Series will not operate while the doors are open.

Comprehensive machine enclosures and tamper-proof safety interlock switches are installed on all quick-acess guard doors, assuring the ROTA-TAB MSP Series will not operate while the doors are open.| ROTA-TAB MSP Series | |||

| SPECIFICATIONS | |||

| Model Number | 1223D | 828B | 835BB |

| Number of Stations | 23 | 28 | 35 |

| Tooling Type | D | B | BB |

| Maximum Tablet Diameter Solid Tooling | .937 | .687 | .500 |

| Maximum Tablet Diameter inserted Tooling | .812 | .562 | .500 |

| Main Pressure | 12 Tons | 8 Tons | 8 Tons |

| Pre-compression Pressure | 5 Tons | 5 Tons | 5 Tons |

| Maximum Powder Fill Depth | .812 | .812 | .812 |

| Maximum Tablet Thickness | .437 | .437 | .437 |

| Tablets Per Minute | 1950 | 2800 | 3500 |

| Main Motor 230/460 Volts | 10 HP | 7.5 HP | 5 HP |

| Machine Height | 73″ | 73″ | 73″ |

| Machine Floor Space | 35″x33″ | 35″x33″ | 35″x33″ |

| Machine Weight | 4240 lbs | 4240 lbs | 4240 lbs |

| The ROTA-TAB is American-engineered and “Made in the U.S.A.” – assuring premium-quality parts and availability. | |||